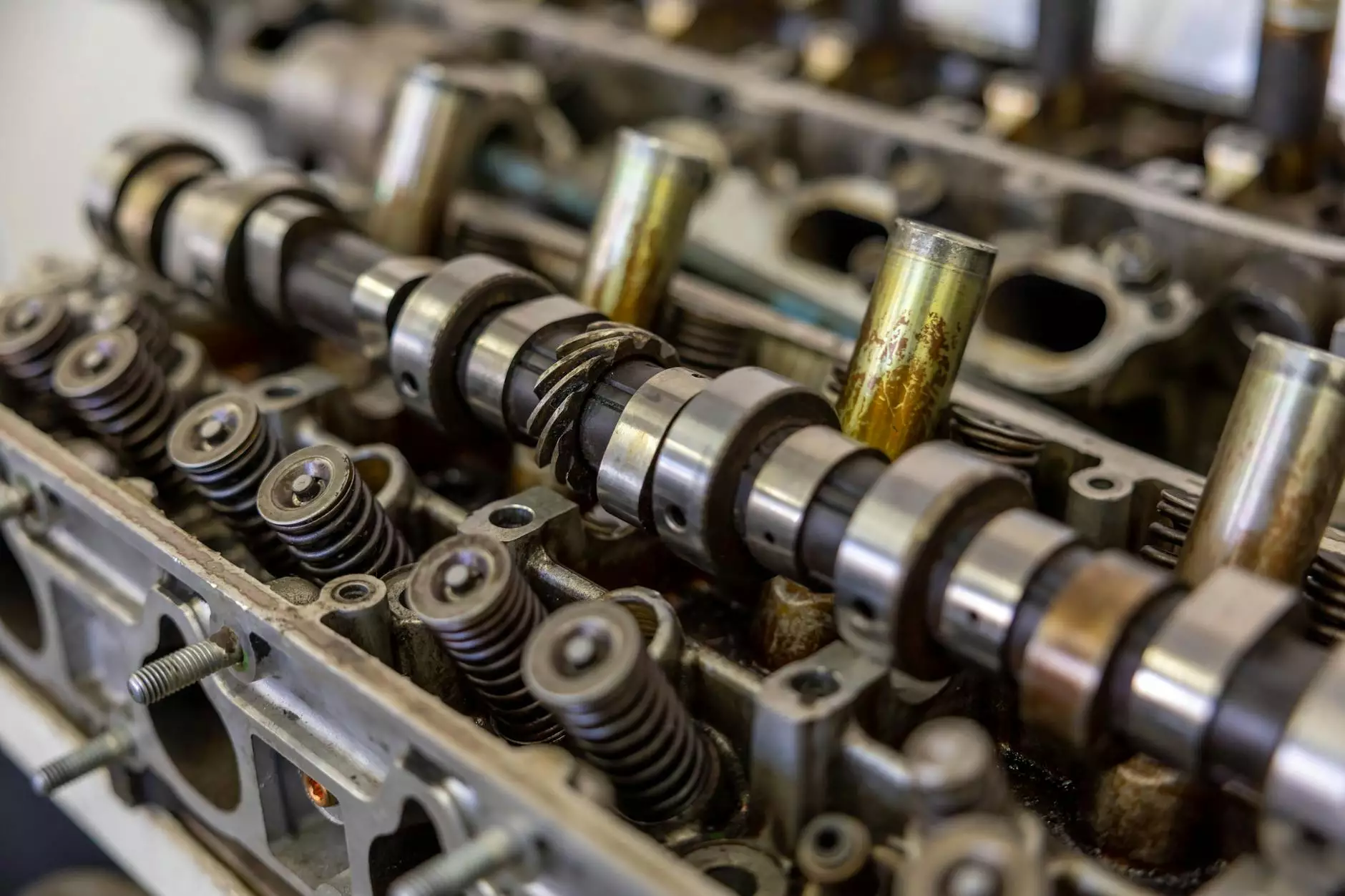

The Essential Parts of a Crankshaft in Diesel Engines

The crankshaft is a fundamental component in any diesel engine that plays a crucial role in converting the linear motion of the pistons into rotational motion, which ultimately powers the vehicle. Understanding the parts of a crankshaft is vital for anyone involved in the maintenance and repair of diesel engines, from mechanics to parts suppliers. In this comprehensive article, we will delve into the various parts of the crankshaft, their functions, and their importance in the efficient operation of diesel engines.

What Is a Crankshaft?

A crankshaft is a mechanical component that transforms the rectilinear motion of the engine pistons into rotational motion, which can then be used to power the vehicle. It is crucial in converting the explosive energy produced during combustion into usable power, making it an indispensable part of the engine system. The crankshaft is typically made of high-strength steel or cast iron, designed to withstand the extreme forces generated within a diesel engine.

Key Parts of a Crankshaft

The crankshaft consists of several key components, each contributing to its functionality. Let’s explore these parts in detail:

1. Main Journal

The main journal is the central portion of the crankshaft that is mounted in the engine block. It supports the crankshaft's rotation and ensures its alignment. Each main journal is lubricated with engine oil, reducing friction during operation. The strength and stability of the main journal are vital for the overall performance and durability of the crankshaft.

2. Crank Pins

Crank pins are the protruding sections of the crankshaft that connect to the connecting rods. They are crucial in transferring motion from the pistons to the crankshaft. The crank pin's design allows it to pivot as the piston moves, facilitating the conversion of linear motion into rotational energy. Proper alignment and maintenance of crank pins are essential to prevent excessive wear and potential engine failure.

3. Counterweights

Counterweights are strategically placed on the crankshaft to balance the rotating assembly. They help offset the uneven forces generated during combustion cycles, minimizing vibrations and ensuring smoother engine operation. The design and placement of counterweights are critical for maintaining engine balance, improving fuel efficiency, and prolonging the engine's lifespan.

4. Webs

The webs are the sections of the crankshaft that connect the main journals to the crank pins. They provide structural integrity and strength to the crankshaft while allowing for efficient oil flow through the engine. The design of the webs must be robust enough to withstand the stresses imposed during high-performance operations yet lightweight to facilitate smooth rotation.

5. Keyways

Keyways are grooves machined into the crankshaft that accommodate keys used to lock various components, such as the pulley or flywheel, in place. These ensure that the components rotate synchronously with the crankshaft, preventing slippage during operation. Keyways must be precisely engineered to avoid failure and ensure a secure fit.

Functionality of a Crankshaft

The functionality of a crankshaft revolves around its ability to convert energy efficiently. Here are the key functions:

- Conversion of Motion: The primary function is to convert the linear motion of the piston into rotational motion, which powers the vehicle.

- Power Transfer: It transmits power from the combustion process to the drivetrain, enabling vehicle movement.

- Balance and Vibration Reduction: The crankshaft's design, featuring counterweights and web structures, helps maintain engine balance, minimizing vibrations.

- Support for Engine Components: It provides a mounting point for other vital components, such as the timing gear and the oil pump.

Importance of Crankshaft Maintenance

Proper maintenance of the crankshaft and its parts is essential for the longevity and performance of diesel engines. Here are key maintenance practices:

Regular Inspections

Inspect the crankshaft regularly for signs of wear, cracks, or deformation. Early detection of these issues can save significant repair costs.

Lubrication

Ensure that the crankshaft is adequately lubricated with high-quality engine oil. Proper lubrication reduces friction and wear, prolonging the life of the crankshaft.

Balancing

Regularly check and maintain the balance of the crankshaft to prevent excessive vibrations which can lead to further mechanical issues and increased wear on other components.

Replacement of Worn Parts

If any parts of the crankshaft, such as the crank pins or main journals, show signs of significant wear, they should be replaced promptly to avoid catastrophic failure.

How Crankshaft Design Affects Engine Performance

The design of the crankshaft directly influences the performance characteristics of a diesel engine. Here are several ways how:

1. Engine Efficiency

A well-designed crankshaft improves the overall efficiency of the engine. By optimizing the shape and weight of the crankshaft, engineers can enhance fuel economy and performance output.

2. Acceleration

The relationship between the crankshaft's mass and its moment of inertia plays a crucial role in the engine’s ability to accelerate. A lighter crankshaft allows for quicker acceleration, which is particularly important in high-performance applications.

3. Durability

Engineers must choose the appropriate materials and design features to ensure that the crankshaft can withstand various loads over its lifetime. Advanced materials can enhance durability, reducing the risk of failures.

Crankshaft Upgrades and Modifications

To further enhance engine performance, some diesel enthusiasts consider crankshaft upgrades and modifications. Here are a few common options:

1. Lightweight Crankshafts

Replacing a factory crankshaft with a lightweight version can reduce the overall engine weight, enhancing acceleration and performance.

2. High-Performance Crankshafts

Upgrading to high-performance crankshafts designed for specific power outputs can improve engine responsiveness and overall horsepower.

3. Custom Balancing

Custom balancing can enhance the smoothness of operation and minimize vibrations, contributing to a more refined driving experience.

Finding Quality Crankshaft Parts at Client-Diesel.com

When it comes to sourcing diesel engine parts, including high-quality crankshafts and their components, client-diesel.com offers a comprehensive selection tailored to meet various engine specifications. Here’s why it’s beneficial to choose their services:

1. Extensive Product Range

Client-Diesel.com features a wide array of diesel engine parts, including OEM and aftermarket options, to suit both standard and high-performance applications.

2. Quality Assurance

All products sourced are subjected to rigorous quality checks, ensuring that customers receive only the best components that enhance engine reliability and performance.

3. Expert Support

The experienced team at Client-Diesel is available to provide expert guidance on selecting the right parts for your engine needs, aiding in informed purchasing decisions.

4. Competitive Pricing

With a commitment to offering competitive pricing, client-diesel.com makes sourcing quality parts affordable for everyone, from individual mechanics to large enterprises.

Conclusion

Understanding the parts of a crankshaft is essential for anyone involved in the maintenance and performance enhancement of diesel engines. From the main journal and crank pins to counterweights and webs, each component plays a vital role in the engine's operation. Regular maintenance, proper lubrication, and timely replacements can significantly extend the lifespan of the crankshaft, enhancing overall engine efficiency and performance. For superior quality diesel engine parts, look no further than client-diesel.com, where you will find everything you need to keep your diesel engines running at their best.